Table of Contents

ToggleArtificial Intelligence (AI) is changing the way businesses handle supply chains. From managing inventory to tracking deliveries, AI is making everything faster, smarter, and more efficient. Traditional systems often make mistakes or take too much time. But with AI solutions, companies can now predict demand, avoid stockouts, and save costs.

This article explains how AI in supply chain management helps businesses improve inventory management, reduce errors, and stay ahead in a competitive market.

What Is AI in Supply Chain?

AI in the supply chain means using smart technology to help manage tasks like tracking products, balancing inventory, and planning delivery routes. It works faster and better than old systems.

AI uses data to learn and improve. It can understand voices, read messages, and even predict the future. In supply chain management, this means AI can:

- Forecast customer demand

- Suggest better delivery routes

- Spot quality control issues

- Reduce delays in shipping

With AI in supply chain management, businesses can manage their stock more wisely and serve customers faster. It saves time, cuts costs, and helps make better decisions every day.

The Evolution of Artificial Intelligence in Supply Chain Management

AI didn’t become smart overnight. It took time to grow. There are various stages of evolution of AI in Supply Chain:

- 1980s - The Early Days: Businesses used simple AI systems to help with basic tasks like managing stock and planning delivery routes.

- 1990s - Smarter Decisions: Companies like Walmart began using data mining and early machine learning to predict customer needs and improve planning.

- 2000s - Real-Time Action: AI grew stronger with the rise of the internet and big data. Businesses could now adjust plans in real-time and design smart supply networks.

- Today - Total AI Integration: Now, AI is used in every part of the supply chain. From ordering supplies to delivering them to the customer, AI services handle it all. These tools can:

- Predict demand with high accuracy

- Track inventory across multiple locations

- Optimize delivery and logistics with AI solutions for logistics

This growth shows that AI integration in supply chain management is no longer optional but it’s necessary.

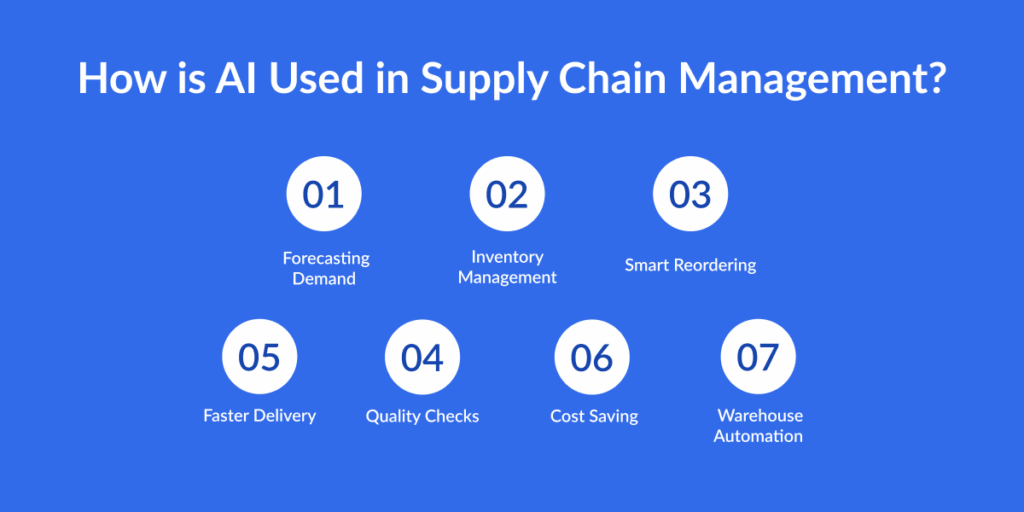

How is AI Used in Supply Chain Management?

AI helps at every step of the supply chain. Here’s how it works:

1. Forecasting Demand

AI studies customer behavior and sales data. It tells businesses what items people will need and when, so they don’t run out of stock.

2. Inventory Management

AI in inventory management makes sure that companies have the right amount of stock. Not too much. Not too little.

3. Smart Reordering

When stock is low, AI systems can automatically reorder supplies. This saves time and avoids delays.

4. Faster Delivery

AI solution for logistics tracks traffic, weather, and delivery routes. It finds the best way to get products to customers on time.

5. Quality Checks

AI tools watch for problems in packaging, production, and storage. They alert teams early before customers face any issues.

6. Cost Saving

AI reduces waste, prevents errors, and uses fewer resources. This means companies spend less while doing more.

7. Warehouse Automation

AI can guide robots and machines inside warehouses to pick, pack, and move items without human help.

With AI integration, supply chain systems become smarter every day. Businesses work better and serve their customers faster.

Advancements in AI-driven Supply Chain Optimization

Day by day there are more advancements in AI for supply chain management. With smart systems and tools, companies can now make better decisions, work faster, and reduce waste.

Some of the latest advancements in AI-driven supply chain optimization:

1. Machine Learning for Demand Forecasting

AI systems can study past sales, weather, and market trends to predict what products people will want. This helps companies avoid running out of stock or ordering too much.

2. Reinforcement Learning for Smarter Inventory Control

This AI method learns through trial and error. It helps businesses figure out the best time to reorder items and how much to keep in stock.

3. Natural Language Processing (NLP)

AI can read customer reviews, social media posts, and news to understand what people like. This helps plan inventory better based on real customer opinions.

4. Computer Vision for Automated Checks

AI cameras and sensors can scan products in real-time, track what’s in the warehouse, and spot any damaged goods.

5. Predictive Analytics for Maintenance

AI systems can study machine data to predict when a machine might break. Fixing things early means fewer delays and less money spent on repairs.

6. GANs for Inventory Simulation

Generative AI creates fake (but realistic) data to test different inventory plans. This helps companies see what might happen before making real-world changes.

7. Autonomous Robots for Warehouses

AI robots can move around the warehouse, pick items, and deliver them quickly. This saves time and reduces human effort.

8. Sentiment Analysis for Demand Sensing

AI reads what people are saying online to figure out what they want. This helps businesses adjust their stock levels accordingly.

9. Multi-Echelon Inventory Optimization (MEIO)

AI balances inventory across different locations, factories, warehouses, and stores to avoid fluctuations in stock like adding too much or too little stock.

10. Predictive Stock Replenishment

AI systems track sales and inventory in real-time. They automatically reorder items before they run out.

These smart AI solutions help businesses save time, reduce costs, and keep customers happy.

Impact of AI in Supply Chain Management

The impact of AI in supply chain management is huge. It’s helping companies become faster, smarter, and more efficient.

- It automates tasks like stock checking and order processing.

- It improves customer service by tracking orders in real-time.

- It reduces human error and saves money.

- It helps predict problems before they happen.

With AI in inventory management, businesses can work better and keep up with changing customer demands.

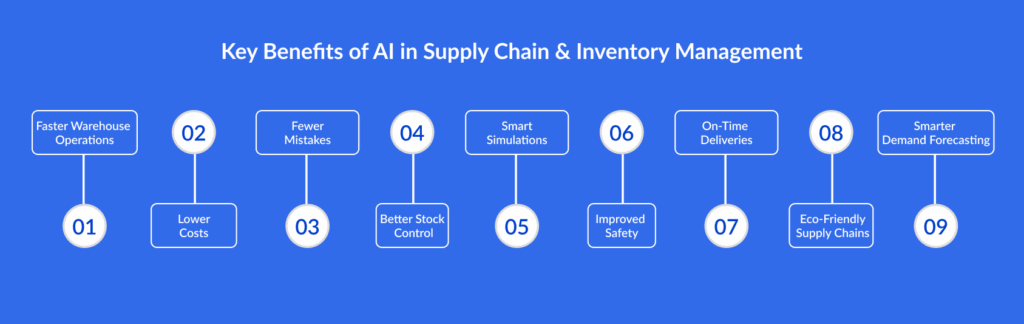

Key Benefits of AI in Supply Chain & Inventory Management

There are many benefits of AI in Supply Chain Management and AI in Inventory Management helps businesses work smarter and faster.

1. Faster Warehouse Operations

AI suggests the best layout for racks and shelves so workers or robots can move quickly. It also finds the fastest routes for picking items, which saves time and speeds up delivery. This helps in getting orders ready and shipped much faster.

2. Lower Costs

AI helps companies spend less by reducing waste and saving energy. It watches machine health and predicts problems before they cause breakdowns. This means fewer repairs and no sudden downtime, which saves a lot of money.

3. Fewer Mistakes

AI quickly catches errors like placing the wrong item in an order or sending damaged goods. It checks inventory using cameras and sensors to avoid manual mistakes. This leads to fewer returns, less waste, and happier customers.

4. Better Stock Control

AI tracks real-time stock and predicts what’s more required to add in the inventory. It makes sure there is enough of each item. This keeps shelves full without wasting money on extra stock.

5. Smart Simulations

AI lets companies test different ideas before trying them in real life. For example, they can see what happens if they move a warehouse or change a delivery route. This helps them make smarter decisions without any risk or loss.

6. Improved Safety

AI tracks worker safety using cameras and smart wearables. It checks if safety gear is worn and warns about risky movements. This reduces accidents and creates a safer working space for everyone.

7. On-Time Deliveries

AI finds the fastest delivery paths and updates them if there’s traffic or bad weather. It makes sure all parts or packages reach on time, avoiding production delays. Customers also get better delivery updates and faster service.

8. Eco-Friendly Supply Chains

AI helps cut down fuel usage by planning smarter delivery routes. It also reduces waste and supports recycling by avoiding overproduction. This makes the supply chain better for the planet and more sustainable.

9. Smarter Demand Forecasting

AI studies past sales, trends, and even customer reviews to guess what people will buy next. It helps companies prepare for busy times and avoid slow-moving stock. This makes planning easier and improves profits.

These smart benefits show why businesses are choosing AI services and solutions to improve their supply chains.

By adding AI in Inventory Management and AI integration in Supply Chain Management, companies can work faster, safer, and more efficiently.

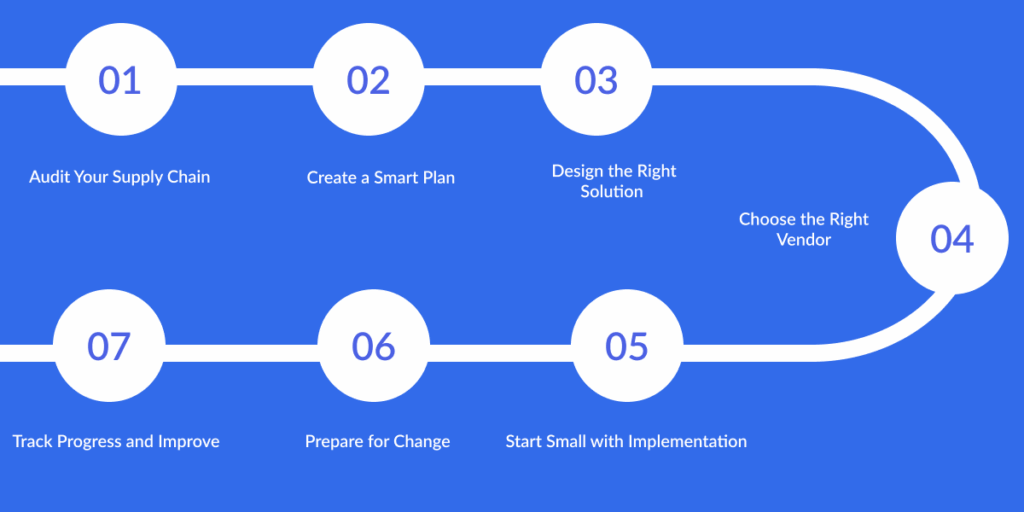

How to Prepare Your Supply Chain for AI?

Before using AI in supply chain management, it’s important to prepare the right way. Here’s a simple step-by-step guide to help businesses get ready:

1. Audit Your Supply Chain

Start by checking every part of your supply chain to find slow, expensive, or confusing areas. Look for places where mistakes happen often or where delays cost time and money. This helps you know where AI can bring the most improvement.

2. Create a Smart Plan

Don’t try to change everything at once. Set clear goals, list out the main problems, and break the AI journey into small steps. A smart plan makes it easier to track progress and avoid mistakes along the way.

3. Design the Right Solution

Check out what tools and systems you’ll need. For example, you may need cloud software, smart sensors, or warehouse robots. Make sure all your systems can connect and work well together.

4. Choose the Right Vendor

Pick a trusted software development company company that offers the best AI solutions for your needs. Check if they have a good support team, fair pricing, and experience in your industry. This helps build a strong and long-term partnership.

5. Start Small with Implementation

Take little steps in the beginning. Begin with one AI project, like stock tracking or delivery route planning. Test it out, train your team on how to use it, and make sure it works before expanding to other areas.

6. Prepare for Change

AI might feel new or scary to some employees. Talk to your team, explain why AI is useful, and show how it can make their jobs easier and safer. Good communication builds trust and support for the changes.

7. Track Progress and Improve

Once AI is working, timely check its progress, how it is working. Use reports and feedback to see what’s working and what needs fixing. AI keeps getting smarter over time, so keep updating and improving the system.

Challenges of Using AI in the Supply Chain

| Challenge | Why It Happens | What It Means for You |

|---|---|---|

| Training Costs | Workers need to learn new tools and grow comfortable with them. | Extra classes, practice time, and short pauses in regular work can feel pricey at first, but they build long-term skills. |

| Startup & Data Costs | Good AI in inventory management relies on clean, accurate data, collecting and cleaning it can take time and money. | If the data is messy, the system’s answers will be messy too (“garbage in, garbage out”) |

| High-Power Computers | Training big machine-learning models needs fast GPUs or strong cloud servers. | Monthly cloud bills may jump at first, but smart scaling keeps them under control later. |

| Complex Systems | Sensors, robots, edge devices, and software all talk to each other. | Teams must watch these moving parts and fix small problems early before they grow. |

| Change Management | New tech can feel scary to staff used to old habits. | Clear goals, simple steps, and steady coaching help everyone trust the new AI solution for logistics. |

Real- World Example of AI in Inventory Management

A few use cases of AI in inventory management:

1. Walmart - Automatic Re-Stocking

Walmart’s AI looks at sales speed, shelf life, and supplier reliability. It orders fresh stock before shelves run empty, so shoppers always find what they need.

2. Procter & Gamble (P & G) - Demand Forecasting

P & G’s machine learning system studies huge data sets, past sales, ads, and market trends. It predicts demand with high accuracy, cutting both stockouts and overstocks.

3. Amazon - Weather-Aware Planning

Amazon’s AI watches weather reports plus customer clicks and past orders. It shifts inventory closer to buyers when storms slow down roads, keeping delivery promises.

4. General Electric (GE) - Predictive Maintenance

GE fits factory machines with sensors. AI spots tiny warning signs and schedules repairs early, slashing downtime and keeping spare-parts stock lean.

These clear success stories prove that AI in supply chain management raises speed, saves money, and keeps customers smiling.

Invest for AI in Supply Chain with Developer Bazaar Technologies

Developer Bazaar Technologies delivers end-to-end AI solutions for every node in your flow from raw materials to last-mile drop-off.

- Unified Platform: We link planning, purchasing, transportation, and warehouse apps so data travels with your goods.

- Built-In Intelligence: Our cloud tools pack pre-trained models for demand sensing, route planning, and quality checks.

- Fast AI Integration: Whether you use ERP, WMS, or custom apps, our experts plug in AI services with minimal downtime.

- Scalable & Secure: Pay only for the computing power you use, and protect data with enterprise-grade security.

Conclusion

AI is no longer just a fascinating tool, now it is a must-have for businesses that want to stay ahead in today’s competitive market. From reducing waste and avoiding stock outs to predicting demand and improving delivery timelines, AI in supply chain management offers unmatched efficiency.

Still, implementing AI comes with its own set of challenges, like high startup costs, complex systems, and training requirements. But with the right AI development services partner, challenges can be managed smoothly.

Whether you’re a retail giant like Walmart or a growing business, AI services can help you unlock smarter, faster, and greener supply chain operations.

FAQs

1. How does AI help in inventory management?

A: AI helps by analyzing sales data, predicting future demand, spotting stock issues early, and even automating reordering. This ensures the right products are available at the right time without overstocking.

2. What are some real-world examples of AI in inventory management?

A: Top companies like Amazon, Walmart, and GE use AI for tasks like demand forecasting, automatic restocking, predictive maintenance, and more. These help them save money, avoid delays, and serve customers better.

3. Is it expensive to use AI in the supply chain?

A: There can be initial setup and training costs, but many cloud-based AI services offer flexible pricing. Plus, the savings in time, labor, and waste usually make up for the costs in the long run.

4. How can small businesses start using AI in inventory or logistics?

A: Small businesses can start by using simple AI tools like demand prediction software or smart inventory apps. Over time, they can upgrade to advanced systems with the help of AI service providers.

5. What’s the future of AI in the supply chain?

A: The future includes full automation, digital twins for testing ideas, real-time edge computing, and green AI to make operations more eco-friendly.

8. Who can help implement AI in my supply chain?

A: Developer Bazaar Technologies is an expert in AI integration for supply chain and logistics. They offer end-to-end support from planning to full deployment.

RM Mishra

Co-Founder

Developer Bazaar technologies